AquiSense

Transportation

UV LED Disinfection – Robust, Lightweight, Flexible Design

Water disinfection for transportation applications comes with a variety of challenges – durability, weight, and power consumption are just a few examples.

Water disinfection challenges for transportation

Whether water disinfection is needed for a fleet of planes, a new line of trains, or even private RVs or boats, clean water is vital for the health of each passenger aboard.

When a sink is found of these vehicles, it is common to find a water storage system with a tank. When reviewing water quality for commercial airlines, the USEPA found a consistent issue with pathogen growths in the water systems on board.

Current disinfection methods

Carbon or ceramic filters could be used to remove the sediment; however, these filters cannot remove micro organic material allowing bacteria to remain in the system. Bacteria is commonly treated with chemicals, such as chlorine, that leave byproducts in the water to be consumed by unsuspecting customers. Chlorine levels can be difficult to maintain and this is especially true for mobile systems with limited power, space, and personnel. Chlorine treatment also requires periodic testing of the water to ensure the proper level of chlorine is maintained in the water. Further problems exist with the formation of disinfection byproducts from chemical treatment and some chlorine resistant pathogens (e.g. cryptosporidium).

Ultraviolet (UV) systems paired with filters are common alternatives when chemicals are no longer an option. When combined, the filter removes sediment and while the UV light irradiates the bacteria’s DNA making the bacteria incapable of reproducing. However, conventional UV systems utilize fragile, mercury-vapor lamps which are particularly susceptible to breaking in mobile applications. If a lamp was to break during flight, mercury could be absorbed into the water supply. Mercury UV lamps also run on higher voltages and have limited on-off cycles, meaning operational constraints.

UV-C LED Solutions

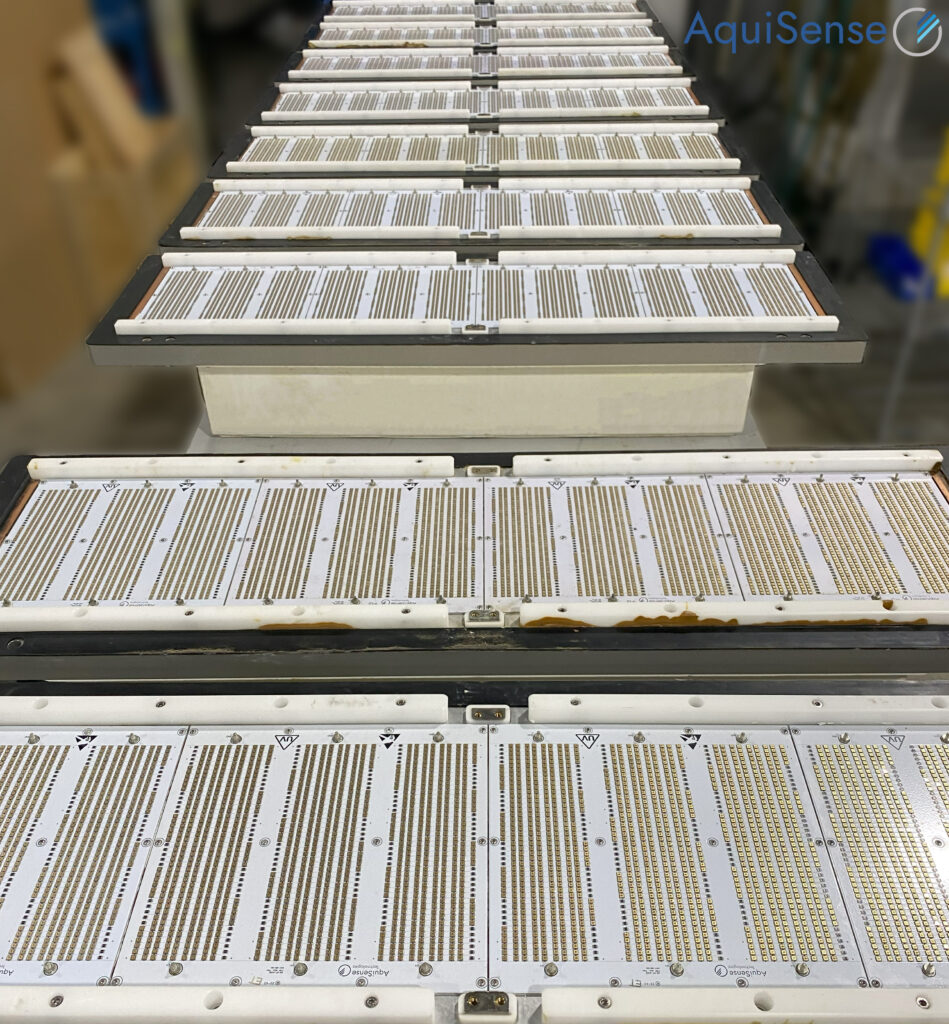

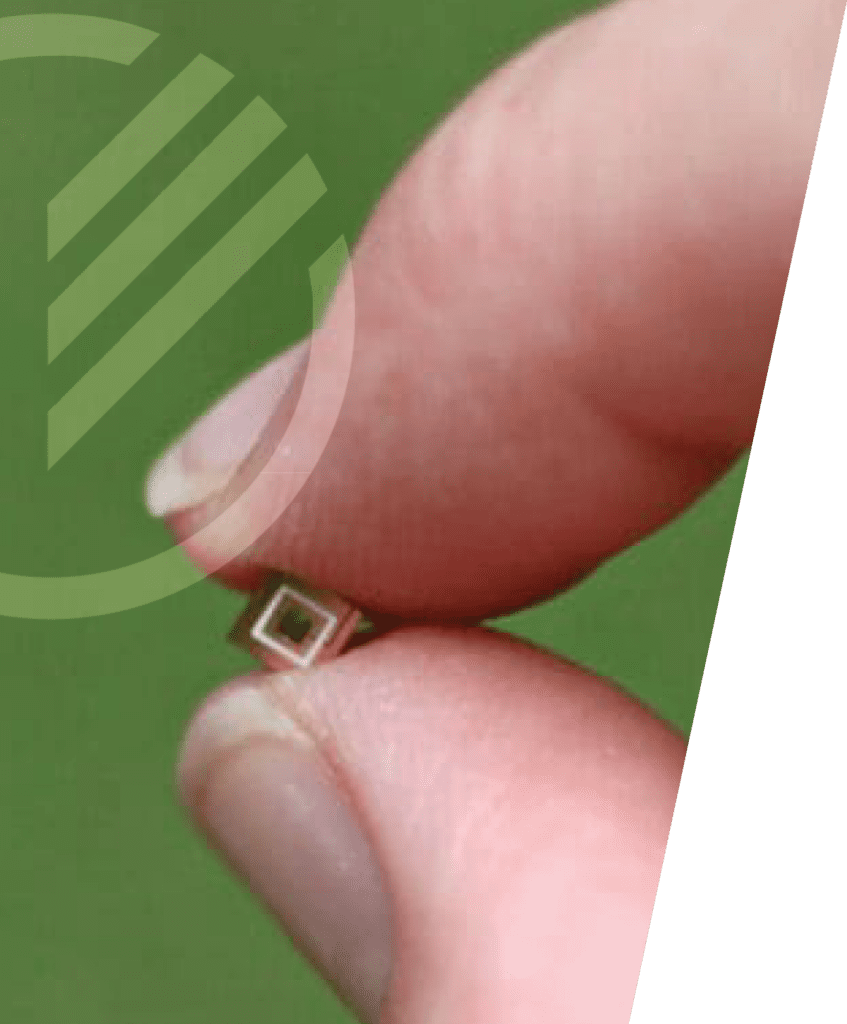

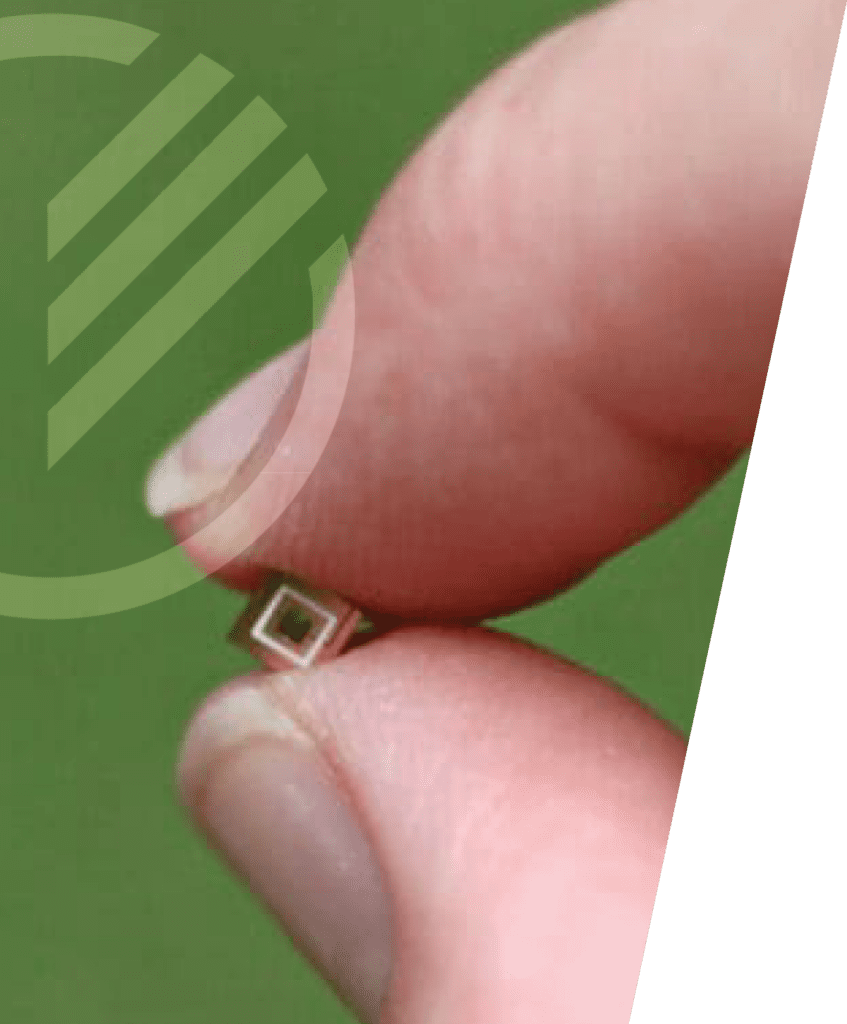

Recently developed LEDs that produce deep ultraviolet light, affect bacteria in the same manner as conventional UV lamps, but offer all the typical benefits of semiconductor technology. UV-C LEDs provide the option for a versatile reactor design that caters to space and weight constraints of airlines. Additionally, LEDs are mercury-free and rugged enough to survive the shock specifications, without any risk of mercury contamination. The small size and instant on/off capabilities mean this technology can be placed near the water dispensing point, such as a sink or galley faucet, and switched on only when water is flowing. Disinfecting the water right before it reaches a user, blocks contamination coming from the piping and diminishes the need for residual disinfection chemicals. This new UV-C LED technology gives a new alternative to an on-going water problem the airline industry has been dealing with for decades.

Test applications

A UV-C LED system is being developed under multiple space programs, including two for the International Space Station. The current ISS’s water system is only 88% efficient and uses filtration and chemical technologies. A 2010 study completed by NASA shows bacteria can still grow inside the current water treatment system and recommended an alternative be developed.

The Bio-contamination Integrated Control of Wet Systems for Space Exploration (BIOWYSE) Project was commissioned by the Horizon 2020 program to address the efficiency and disinfection issues within the ISS water treatment system. BIOWYSE Project is employing UV-C LED technology for water disinfection. This work is showing that UV-C LED systems can be implemented into aerospace applications.

PearlAqua™ in Transportation Settings

- Aerospace

- Commercial airlines

- Boats/Yahts

- RVs/Camper vans

- Trains/public transportation