AquiSense

Mercury Free

UV-C LED Benefits

Enables a lower risk disinfection alternative

Overview

Details

Conventional UV lamps hold their mercury either in a liquid form (more common in medium pressure lamps) or an amalgam (more common in low pressure, high output lamps). Amalgam UV lamps contain solid “spots” which consist of an alloy of mercury and another element, such as indium or gallium. Liquid mercury lamps have the potential to be hazardous both during operation and when the lamp is off. While the lamp is operating the mercury vaporizes; if the lamp is broken, mercury vapor is easily dissolved into the treated product. Accidents and improper procedures increase the risk of exposure to people and the local environment.

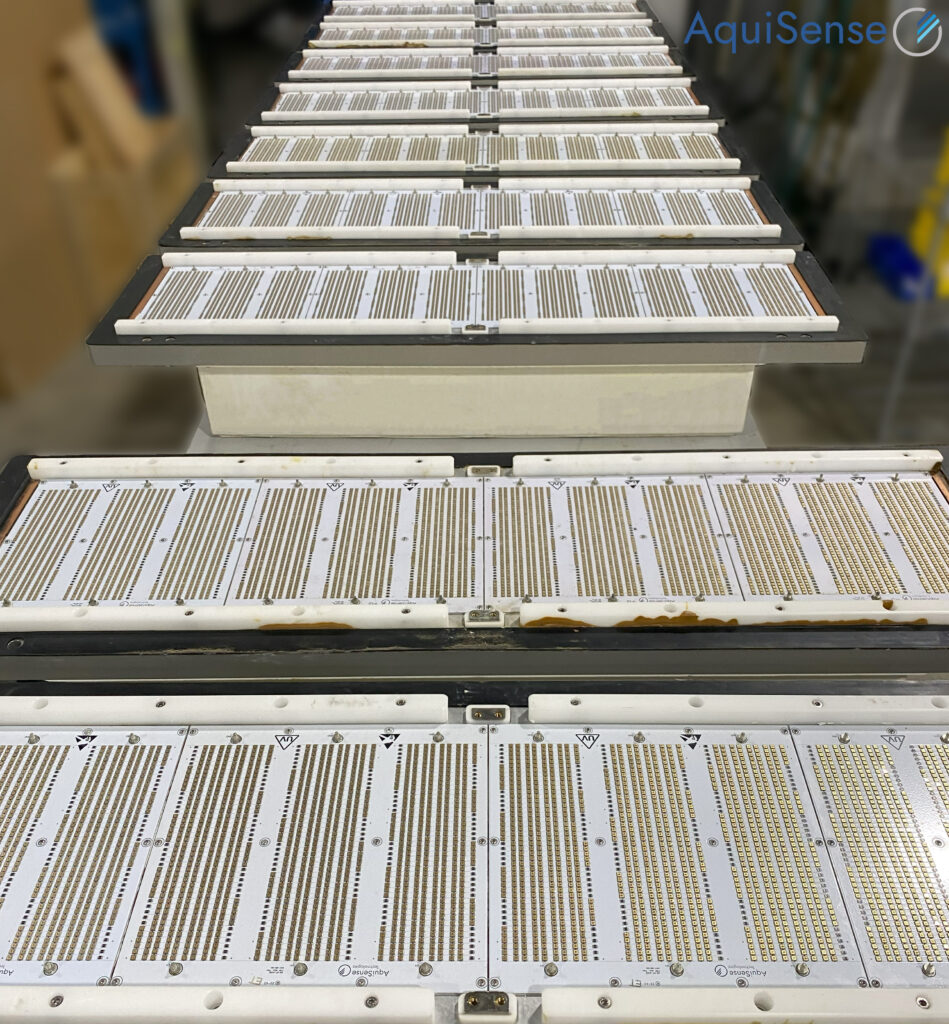

UV-C LEDs do contain small amounts of elements such as the metals gallium and magnesium and the metalloids silicon and boron (although boron is not predominantly used). These metals and or metalloids are bound within a stable crystal structure and cannot leach into the environment.

The inherent stable crystal structure of an LED ensures that UV-C LEDs are very robust to mechanical or environmental shock.

UV-C LED Benefits

- Safer operation and implementation – no risk of lamp breakage

- Reduced personnel and product safety risk – e.g. mercury contamination

- Position for future regulation – e.g. UN Minamata Convention

- Reduced safety costs – e.g. no mercury spill kit and staff safety training

Action

UV-LEDs’ mercury-free status has led to these systems being incorporated into medical devices and aerospace applications where conventional UV systems were often discounted due to potential breakage and contamination risk.

UNEP Minamata Convention

The Minamata Convention on Mercury was initiated by the United Nations Environmental Programme (UNEP) to protect human health and the environment from anthropogenic emissions and releases of mercury. The UNEP has set the goal for mercury to be phased out of production by the year 2020.

In 2013, the UNEP asked organizations and governments to discourage the use of mercury starting immediately unless there is a substantial benefit to the environment and human health. As of August 2017, the convention has been ratified and has officially entered into force.

Although the Minamata Convention does not specifically prohibit the manufacture and sale of UV mercury-vapor lamps, it will provide a generally positive influence for the more widespread adoption of alternative technologies. Potential responses may include the following actions:

- Corporations that use UV systems in products or manufacturing processes (e.g. white goods, beverage, microelectronics, life sciences) may implement best practices by selecting an LED option by the influence of the Minamata Convention, not by enforcement.

- Original Equipment Manufacturers that currently employ conventional mercury lamps may see a conflict with the use of mercury-based products to their own environmental policies and, based on Minamata regulations, might start a transition to develop new products using mercury-free light sources.

- Municipalities may also follow suit in adopting UV-C LEDs, although it is more likely that they will require more time to adopt the new technology.

- There will always be a percentage of people that will look for “eco-friendly” product options. As the Minamata Convention raises awareness of the effects of mercury, it inherently affects the use of mercury-based lamps without banning the sale or manufacturing of these lamps.

- Regulators will likely have a slow transition from mercury to UV-C LED lamps. Regulators will always look for viable alternatives to mercury, as it is their mandate to steer technology to the most holistically sound solution.